Furniture with a Heart of Steel

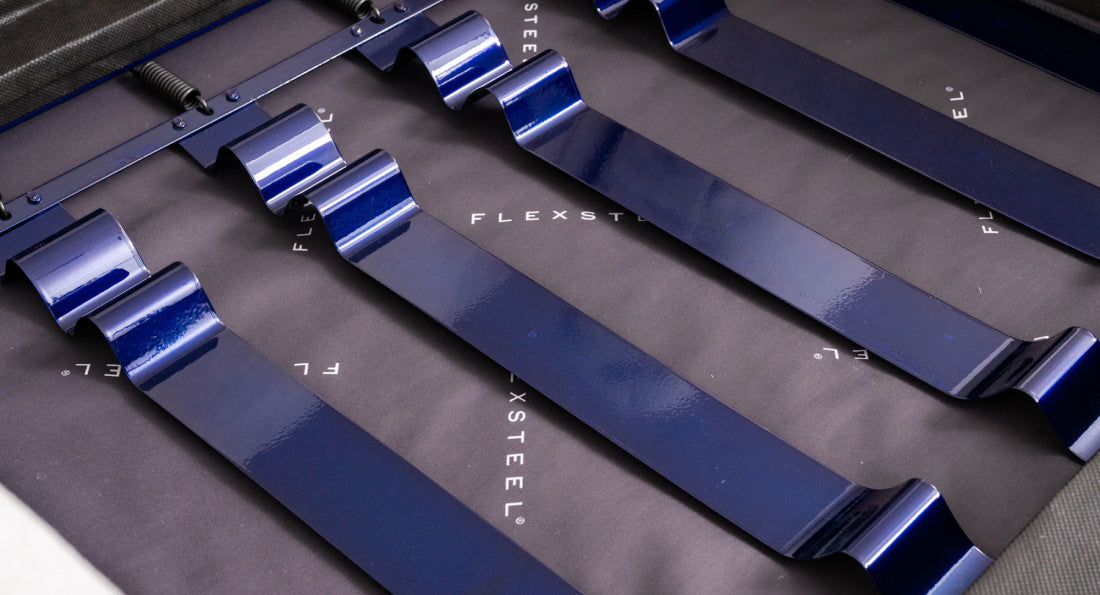

At the heart of our upholstered seating is the Blue Steel Spring™ - a patented spring system providing unmatched comfort, support and durability that has been trusted for more than 100 years. This unique spring system is used exclusively in Flexsteel products.

Since the beginning, we have perfected the original spring design and developed varying adaptations of it to accommodate the advancement in furniture construction and to better serve the needs of our consumers.

Unlike sinuous wire springs, our springs never need retying. All Flexsteel Blue Steel Spring™ systems are powder coated for protection and painted in our signature blue color. We believe so strongly in our spring systems, we guarantee their durability for a lifetime of use.

Nothing to hide here

Our Blue Steel Spring™ is no secret - we have placed it in plain sight so that you know your furniture has its authentic durability. Simply look underneath the bottom of our frames to find the iconic blue seat spring system.

Our Spring Units

C-Flex Spring

Used in the construction of our 5000 Series furniture, the C-flex spring consists of evenly spaced, dual steel ribbons that line the length of the frame from front to back. Each ribbon ends in an arch at the back of the seating area to provide extra support where it’s needed most.

DualFlex Spring

Designed to achieve the latest standard in superior seating comfort, the DualFlex Spring System uses thick, evenly spaced steel ribbons along the length of the frame from front to back.The ribbons are attached to the spring’s frame with resilient helical coils that allow for a wider range of motion. The entire system is securely bolted to the seat frame for extra support.

Blue Ribbon Spring

As the spring that influenced our name, the Blue Ribbon unit has been at the core of our company since the very beginning, and is used in the construction of our 7000 and 8000 Series furniture. Similar to the C-Flex unit, evenly spaced, dual steel ribbons run along the length of the frame from front to back. A solid steel arch is riveted to the back end of each ribbon to provide extra support where it’s needed most. An extra perpendicular steel ribbon bands the entire system together for even more durability.